Replenishment automation that understands service risk and cost

Most service parts organizations already “automate” replenishment.

Yet planners still review and override orders every day. That’s not a change-management problem. It’s a design problem.

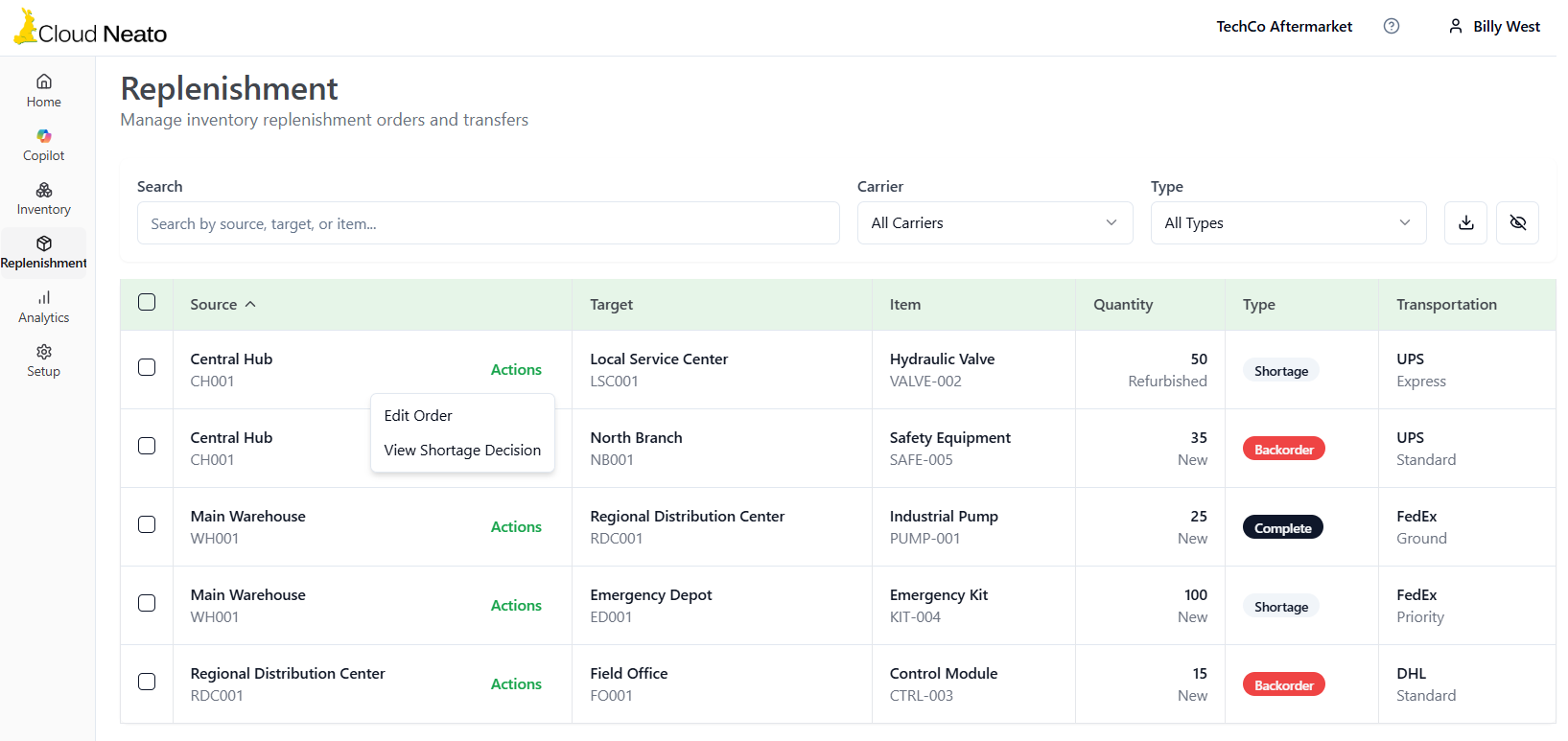

Cloud Neato Replenishment uses a decision layer to automate service parts replenishment by economically balancing service risk against transportation and trade-compliance cost — the same judgment experienced planners apply manually today.

Why replenishment automation breaks in service parts

Traditional replenishment automation is built on a simple assumption:

If inventory falls below a target, place an order.

That logic works in high-volume, low-variability environments.

It breaks down in service parts, where:

- Inventory targets are often one unit

- Demand is uncertain and intermittent

- Replenishment frequently crosses borders

- Shipping a single part can trigger disproportionate freight and customs cost

The result is predictable:

- Excessive single-item shipments

- High expedite and transportation spend

- Trade-compliance friction

- And planners who stop trusting the system

How experienced planners really make replenishment decisions

Great planners are not asking:

“Is inventory below target?”

They are asking:

“Should I ship now — or can I safely wait?”

That single question implicitly balances:

- Risk of service disruption

- Time to recover if service is interrupted

- Cost of shipping now versus later

- Customs minimums and compliance fees

Traditional systems cannot answer this question — so planners do it manually.

Prioritization alone is not enough

Some legacy service planning tools attempt to prioritize shortages.

That helps — but it stops short.

They rank urgency, then still trigger replenishment based on static rules. They do not use that urgency to actively trade off against:

- Shipment consolidation opportunities

-

Customs and trade-compliance minimums

A better model: price the decision

Cloud Neato introduces an explicit decision layer between planning and execution.

Instead of asking “Should we replenish?”, it asks:

“What is the expected cost of waiting one more day — and is that greater than the cost of shipping now?”

To answer that, Cloud Neato calculates Service Risk, based on three dimensions:

-

Likelihood

How likely a stockout is before replenishment arrives -

Recovery Time

How long it would take to restore service if demand cannot be met -

Severity

How critical the part and site are to service outcomes

This converts service uncertainty into an expected business cost — not a binary stockout flag.

Replenishment decisions you can explain — and trust

Because service risk is expressed economically, Cloud Neato can explain decisions clearly:

“Waiting one more day increases expected service risk by $420.”

“Shipping now avoids that risk, but costs $310 in freight and customs.”

This allows the system to automate judgement, not just execution, to confidently:

- Wait for consolidation when risk is low

- Avoid low-value cross-border shipments

- Act immediately when service risk truly dominates cost

Every recommendation is transparent and aligned with how planners already think.

What this unlocks for service organizations

- Fewer single-item shipments — without degrading service

- Lower transportation and customs spend

- Higher planner trust and adoption

- Automation that delegates judgment without abdicating control

This is not about replacing planners. It’s about giving automation the same economic judgment that experienced planners apply manually today.

30-day, no risk evaluation

Cloud Neato Replenishment integrates with your service logistics partner, eliminating dependency on internal IT teams for deployment.

In a short evaluation, we quantify:

- How many replenishment decisions could have waited safely

- Where consolidation opportunities were missed

- How service risk would have changed

- The potential transportation and trade-compliance savings

No black boxes. No excel based value assumptions.

Just your data, analyzed through a decision model built for service-parts reality.